What can it do for you?

Minimise System Downtime

Flexible Maintenance Agreements

Ensure smooth and efficient plant operation

Reduce the risk of breakdown and costly downtime

Maintain the highest levels of performance for reduced operational costs

Adhere to health and safety requirements

What are the key features

What it involves

When things are looked after, you get the best out of them. Spirax Sarco steam system aftercare is here to help get the best out of your equipment and provide you with steam expertise when you need it, 365 days a year.

Steam System Servicing Made Simple.

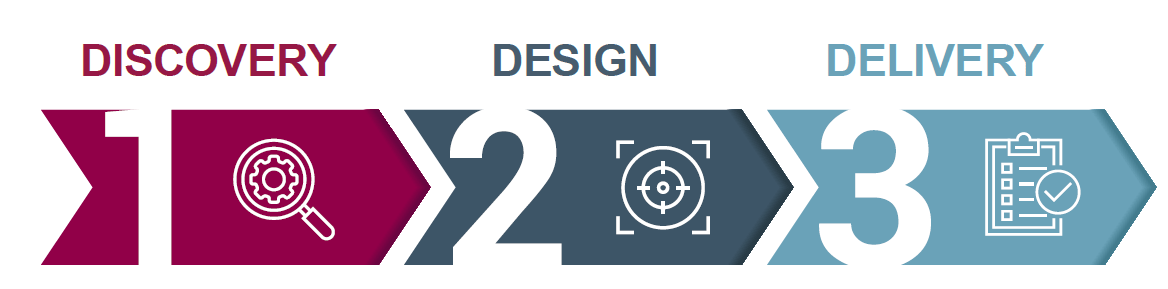

It's as easy as 1-2-3 to extend the life of your equipment. Frequently serviced and well maintained equipment is key to maximising equipment uptime, maximising production output and minimising carbon output. With tailor made service plans designed around your site and goals, our dedicated engineers are here to help take care of what matters.

When you take care of things they last.

A maintenance servicing plan is a simple and affordable way to manage the cost of servicing your steam system equipment. At Spirax Sarco we know that annual servicing can be expensive, which is why our servicing plans are designed to help you avoid any large payments that can be difficult to finance.

With a pay monthly servicing plan, your servicing bills are spread across monthly instalments. All payments are interest free and the cost of servicing is fixed for the duration of the plan, meaning you'll know exactly what you'll have to pay and when with no lump sum payments to worry about.

A servicing plan consists of a schedule of services that are arranged in line with the recommended service requirements for your steam system. Servicing is scheduled every 12 months for the length of your plan, with all servicing completed by a quality-assured technician.

Service Contracts

"We have been working with Spirax Sarco for many years and find their service and components excellent."Mick Cockshott, Projects and Utilities Manager at Daniel Thwaites Brewery View Case Study

Related to Service Contracts

Document downloads

Case Study: Daniel Thwaites achieves energy savings

Steam system maintenance contract cuts Daniel Thwaites Brewery carbon footprint.

Case Study: Steam systems all go at cancer research facility

The Beatson Institute for Cancer Research is a biological research facility that conducts studies into the basic biology of cancer. Discover how a Spirax Sarco Service Contract has steamlined steam system maintenance and mitigated risk of downtime.

Case Study: Cutting the cost of energy and maintenance

The upgrade to Spirax Sarco’s EasiHeat™ steam-to-hot-water solutions and Reverse Osmosis (RO) system in ten plant rooms helped this acute hospital reduce energy and maintenance costs.

Rising fuel prices – what you need to know

For plant managers, two things in life are certain: manufacturing uses a lot of energy; and that energy costs money. In fact, a survey by The Daily Telegraph and YouGov revealed that 28 per cent of manufacturing companies spend more than £250,000 a year on energy . That’s enough to make anyone’s eyes water.

Steam systems all go at cancer research facility

Being held responsible for a facility where vital cancer research is conducted is no mean task for any facilities team. So having confidence that all specialist mechanical services are working at their optimum level is paramount. By streamlining maintenance of its steam systems, the Beatson Institute for Cancer Research has mitigated outstanding risk and freed up in-house resource to focus on what they do best.

Service Contracts the easy way to achieve operational efficiency

Chances are, the most cost-effective way for plant managers to keep their steam system operating at its full potential, is to outsource some, or all, of the maintenance work. A service contract is a flexible way to make sure that a plant maintains peak operational efficiency, ensures equipment longevity and gives the customer peace of mind that all their equipment is safely maintained by dedicated engineers.

The easy way to keep your steam system performing to its full potential

Time. There’s just never enough of it, especially when you’re running a steam system. Your busy job, which is full of deadlines and ever-changing demands, can leave you feeling as though there is no time to stay on top of your steam system’s upkeep.