Control Applications

Contents

Temperature Control applications

Temperature control of the process can be affected using electric, pneumatic, electro-pneumatic and self-acting controls. This Module details some common applications including process vessels, heat exchangers and high temperature fail safe control.

There are a number of reasons for using automatic temperature controls for steam applications:

- For some processes, it is necessary to control the product temperature to within fairly close limits to avoid the product or material being processed being spoilt.

- Steam flashing from boiling tanks is a nuisance that not only produces unpleasant environmental conditions, but can also damage the fabric of the building. Automatic temperature controls can keep hot tanks just below boiling temperature.

- Economy.

- Quality and consistency of production.

- Saving in manpower.

- Comfort control, for space heating.

- Safety.

- To optimise rates of production in industrial processes.

The temperature control system employed should be matched to the system, and capable of responding to the changes in heat load. For example:

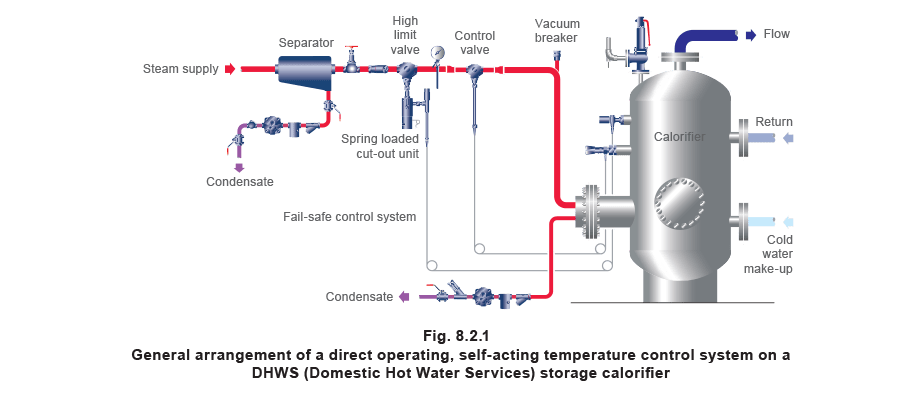

Direct operating, self-acting temperature control

Description

The direct operating, self-acting type of temperature control uses the expansion of liquid in a sensor and capillary to change the valve position.

Advantages:

- Inexpensive.

- Small.

- Easy to install and commission.

- One trade installation.

- Very robust and extremely reliable.

- Tolerant of imperfect steam conditions and of being oversized.

- Self-acting principle means that no external power is required.

- Simple to size and select.

- Many options are available, such as different capillary lengths and temperature ranges.

Disadvantages:

- The control is ‘stand-alone’, and cannot communicate with a remote controller or PLC (Programmable Logic Controller), although a high temperature cut-out may signal closure via a switch.

- Limited sizes.

- Limited pressure ratings.

- Limited turndown.

- Sensors tend to be much larger than the pneumatic and electronic equivalents and also much slower acting.

Applications:

Applications would include those with low and constant running flowrates:

- Small jacketed pans.

- Tracer lines.

- Ironers.

- Small tanks.

- Acid baths.

- Small storage calorifiers.

- Small heater batteries.

- Unit heaters.

Point to note:

The proportional band is influenced by the size of the valve.

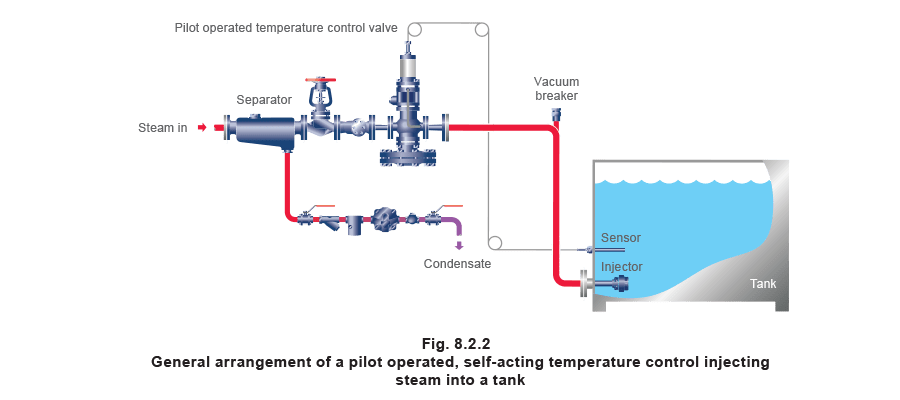

Description

The pilot operated self-acting type of temperature controller uses the expansion of liquid in a sensor and capillary to operate a pilot valve, which in turn changes the main valve position.

Advantages:

- Easy to install and commission.

- One trade installation.

- Very robust.

- Self-acting principle means that no external power is required.

- Simple to size and select.

- Remote adjustment (option).

- Can be switched on and off (option).

- Dual set point (option).

Disadvantages:

- The control is ‘stand-alone’, and cannot communicate with a PLC.

- Small clearances within the valve body mean that steam should be clean and dry to ensure longevity, but this can easily be achieved by fitting a separator and strainer before the valve.

- Proportional only control, however, the proportional offset is much smaller than for direct operating, self-acting controls.

Application:

- Jacketed pans.

- Tracer lines.

- Tanks.

- Acid baths.

- Hot water storage calorifiers.

- Heater batteries.

- Unit heaters.

Point to note:

- The temperature ranges of controllers tend to be narrower than direct operating, self-acting controls.

- Installation must include a strainer and separator.

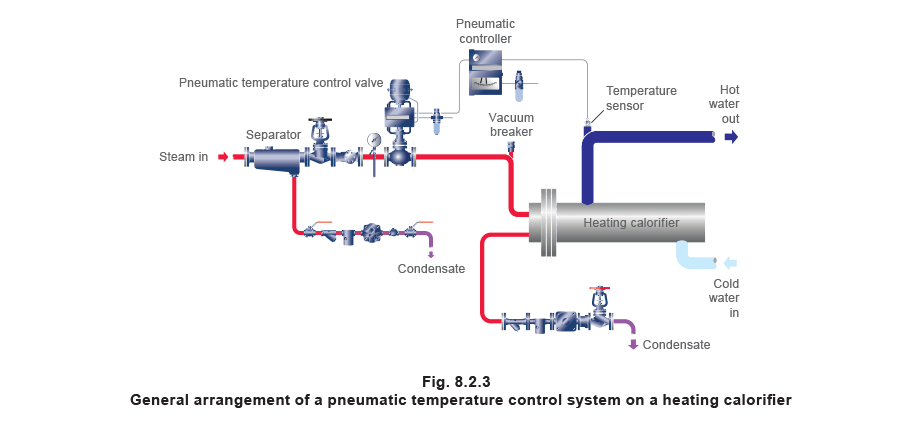

Pneumatic temperature control

Description

These control systems may include:

- P + I + D functions to improve accuracy under varying load conditions.

- Set point(s), which may be remotely adjusted.

Advantages:

- Very accurate and flexible.

- No limit on valve size within the limits of the valve range.

- Excellent turndown ratio.

- Suitable for hazardous environments.

- No electrical supply required.

- Fast operation means they respond well to rapid changes in demand.

- Very powerful, and can cope with high differential pressures.

Disadvantages:

- More expensive than direct operating controls.

- More complex than direct operating controls.

Application:

- Which need accurate and consistent temperature control.

- With variable and high flowrates, and/or variable upstream pressure.

- Which require intrinsic safety.

Point to note:

- A clean, dry air supply is required.

- A valve positioner is generally required except for the smallest and simplest of applications. Air is continually vented from the positioner and controller, and there is a need to ensure that this quiescent air flow is acceptable to the surroundings.

- A skilled workforce is required to install the equipment, and instrument personnel for calibration and commissioning.

- The control is ‘stand-alone’, and cannot directly communicate with a PLC.

- The failure mode must always be considered. For example, ‘spring-to-close’ on air failure is normal on steam heating systems, ‘spring-to-open’ is normal on cooling systems.

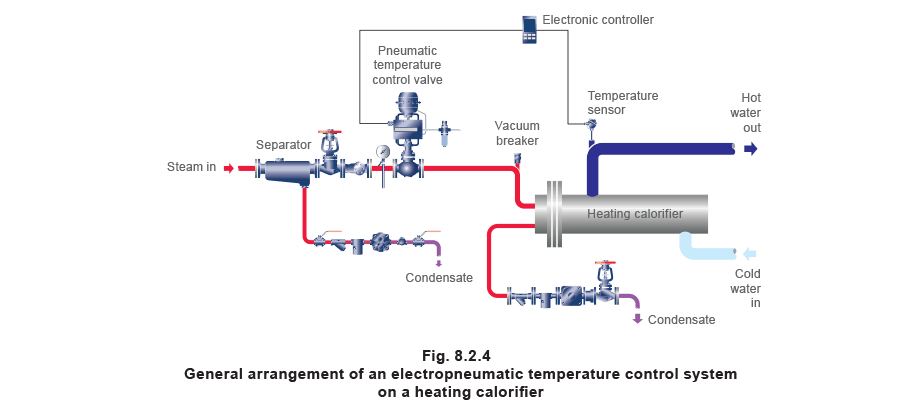

Electropneumatic temperature control

Description

These control systems may include:

- P + I + D functions to improve accuracy under varying load conditions.

- Set point(s) may be remotely adjusted, with the possibility of ramps between set points.

Advantages:

- Very accurate and flexible.

- Remote adjustment and read-out.

- No limit on valve size within the limits of the valve range.

- Excellent turndown ratio.

- Fast operation means they respond well to rapid changes in demand.

- Very powerful, and can cope with high differential pressures.

Disadvantages:

- More expensive than self-acting or pneumatic controls.

- More complex than self-acting or pneumatic controls.

- Electrical supply required.

Application:

- Which need accurate and consistent temperature control.

- With variable and high flowrates, and/or variable upstream pressure.

Point to note:

- A clean, dry air supply is required.

- A skilled workforce is required to install the equipment, electrical personnel are required for power supplies, and instrument personnel to calibrate and commission.

- Can be part of a sophisticated control system involving PLCs, chart recorders and SCADA systems.

- The failure mode must always be considered. For example, ‘spring-to-close’ on air failure is normal on steam heating systems, ‘spring-to-open’ is normal on cooling systems.

- Probably the most common control system - it has the sophistication of electronics with the pace/power of pneumatics.

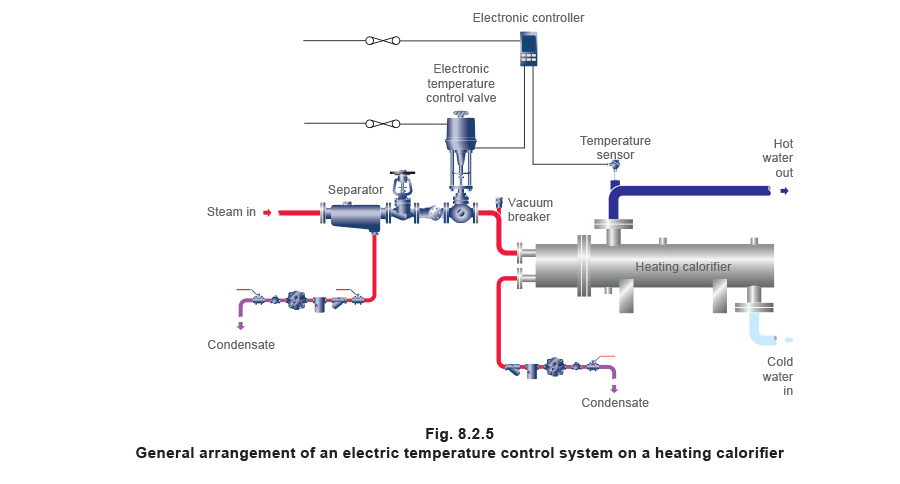

Electric temperature control

Description

These control systems may include:

- P + I + D functions to improve accuracy under varying load conditions.

- Set point(s), which may be remotely adjusted.

Advantages:

- Both controller and valve actuator can communicate with a PLC.

- No compressed air supply is required.

Disadvantages:

The relatively slow actuator speed means they are only suitable for applications where the load changes slowly.

Application:

Space heating of large volumes. For example; warehouses, workshops, aircraft hangars, etc.

Point to note:

- Safety: If electrical power is lost the valve position will not change unless a spring return actuator is used.

- Spring return actuators are expensive, bulky and can only shut off against a limited pressure.

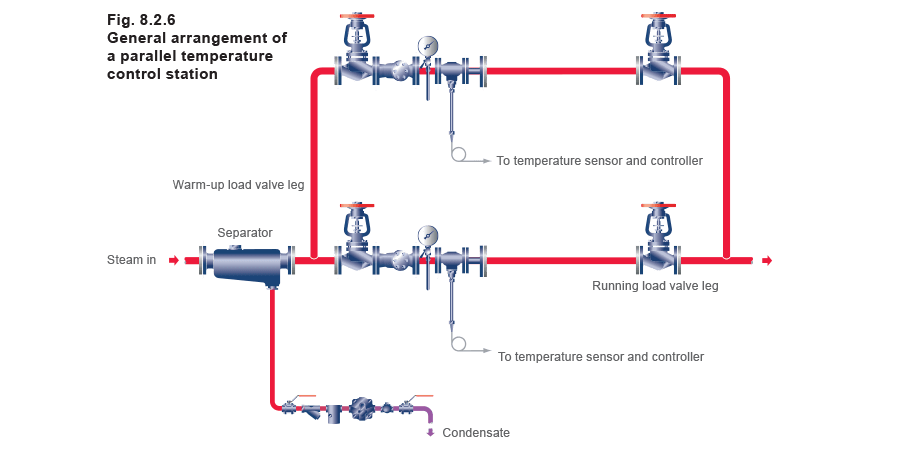

Temperature control (other possibilities) - Parallel temperature control station

Description

An arrangement, as shown in Figure 8.2.6, can be used where the ratio between maximum and minimum flowrates (the flowrate turndown) is greater than the maximum allowable for the individual temperature control valve.

For example, if a specific application has to be brought up to operating temperature very quickly, but the running load is small, and plant conditions dictate that self-acting controls must be used.

To satisfy the application:

- A valve and controller, which could satisfy the running load, would be selected first, and set to the required temperature.

- A second valve and controller, capable of supplying the additional load for warm-up would be selected, and set to a couple of degrees lower than the ‘running load’ valve. This valve is likely to be larger than the running load valve.

With this configuration:

- When the process is cold, both control valves are open, allowing sufficient steam to pass to raise the product temperature within the required time period.

- As the process approaches the required temperature, the ‘warm-up’ valve will modulate to closed, leaving the ‘running load’ valve to modulate and maintain the temperature.

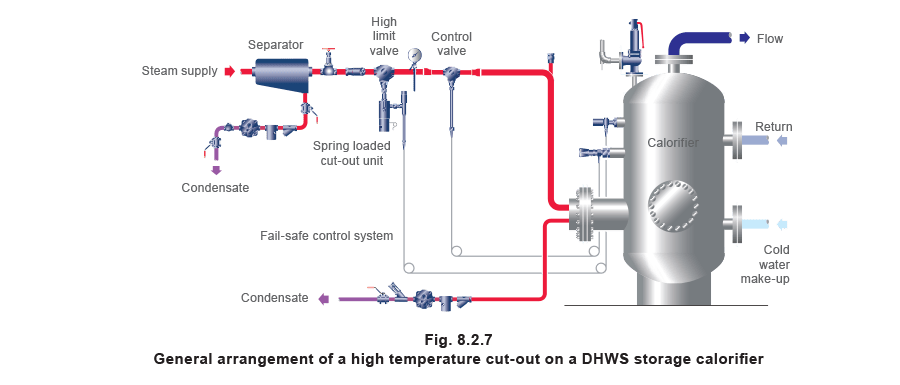

High temperature fail safe control

Description

There are many applications where a totally independent high limit cut-out device is either desirable, or even a legal requirement.

Options:

1. A self-acting control, where the expansion of the fluid releases a compressed spring in a cut-outunit, and snaps the isolating valve shut if the preset high limit temperature is exceeded.

This particular type of self-acting control has additional advantages:

a.It can incorporate a microswitch for remote indication of operation.

b. It is best if it has to be reset manually, requiring personnel to visit the application and ascertain what caused the problem.

2. Spring-to-close electrical actuator where an overtemperature signal will interrupt the electrical supply and the valve will close. This may be accompanied by an alarm.

3. Spring-to-close pneumatic actuators where an overtemperature signal will cause the operating air to be released from the actuator. This may be accompanied by an alarm.

Application:

Domestic hot water services (DHWS) supplying general purpose hot water to users such as hospitals, prisons and schools.

Point to note:

- There may be a legal requirement for the high temperature cut-out to be totally independent. This will mean that the high temperature cut-out device must operate on a separate valve.

- Generally, the high temperature cut-out valve will be pipeline size, since a low pressure drop is required across the valve when it is open.