Are you maximising the potential of your steam system? Are you aware of the hidden opportunities that could significantly impact your energy use and operational efficiency?

Our Steam System Audits will provide you with opportunities to reduce emissions while boosting efficiency and performance in your steam system.

Why Steam System Auditing?

Optimised Energy Efficiency:

Discover untapped potential for energy savings in your steam system. Our comprehensive audits identify areas for improvement, helping you to take action to optimise energy consumption.

Environmental Sustainability:

By optimising energy usage, your steam system can contribute to sustainability goals, reducing your carbon footprint and demonstrating a commitment to responsible business practices. Our steam system auditing will also give you quantifiable sustainability savings data – so you can demonstrate the action you are taking in real terms and justify investments.

Operational Cost Reduction:

Our steam system audits can uncover inefficiencies and recommend targeted solutions, leading to substantial cost and water savings, and also reduced downtime – all ultimately contributing to operational cost reduction.

Increased Equipment Lifespan:

Regular audits ensure that your steam system operates at peak performance. This not only increases the efficiency of your equipment but also extends its lifespan, reducing the need for frequent replacements and repairs.

Enhanced Safety:

Identifying potential hazards and ensuring compliance with safety standards is a crucial aspect of a steam system audit. Our audits will find where you can enhance the safety of your operations, safeguarding your personnel.

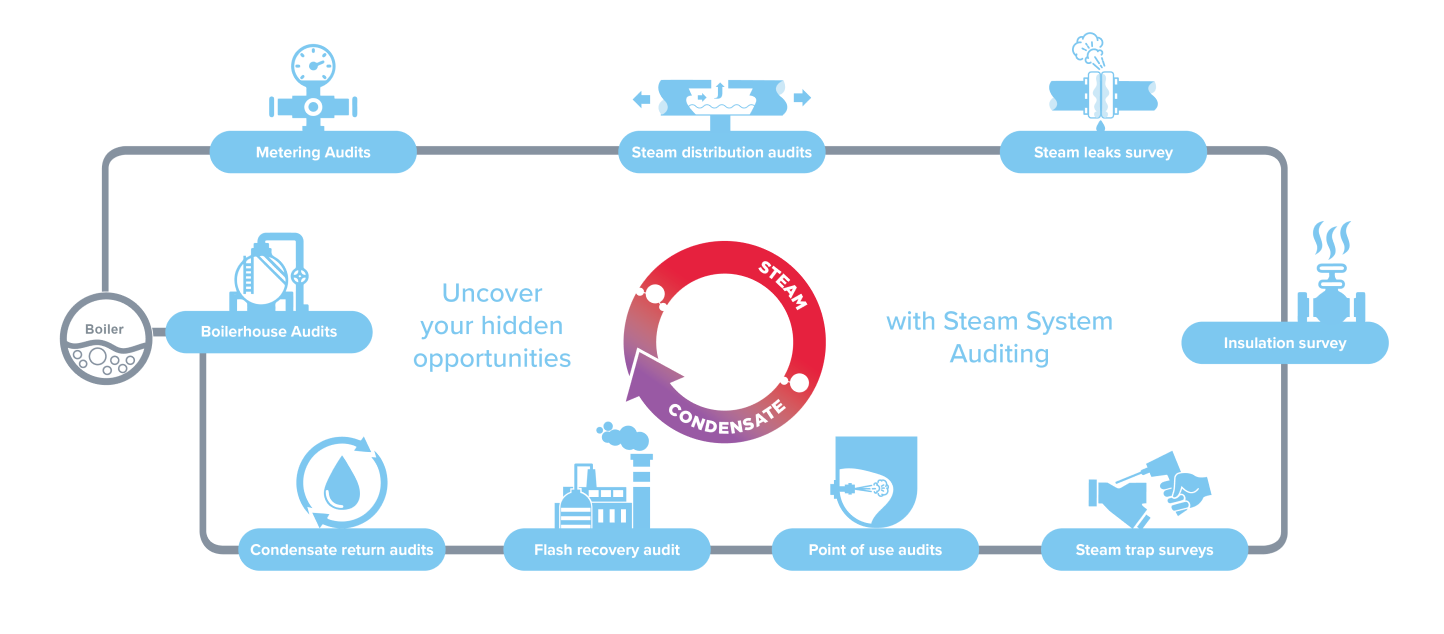

Our most popular steam system audits and their benefits

We offer a range of audits covering all aspects of the steam and condensate loop. Click below to find out more:

Why choose Spirax Sarco?

Experience you can trust:

Our experienced engineers are experts in steam systems. We will leverage our knowledge to provide actionable insights tailored to your unique needs.

We utilise the latest technologies and industry best practices to ensure a comprehensive analysis of your steam system. Our approach combines digitally enhanced solutions with proven methodologies for optimal results.

And we recognise that no two steam systems are alike. We aim to tailor our audits to your specific needs, providing customised solutions that address your unique challenges and opportunities.

Comprehensive Reporting:

Receive a detailed report outlining our findings, recommendations, and a proposed roadmap for implementation. We'll always ensure you have a clear understanding of the report, including the benefits and potential improvements.

Related to Audits for Plant Optimisation

Case Study: Safe sampling

64 Tonnes of CO2 per year saved for fishing products processor.

Case Study: Chemical plant achieves energy savings

Steam Trap optimization saves energy for chemical plant.

Case Study: Oil refinery increases energy savings

Steam trap audit improves machinery performance and achieves energy savings at oil refinery.