Steam Traps and Steam Trapping

Contents

Mechanical steam traps

Mechanical steam traps rely on the difference in density between steam and condensate in order to operate. They can continuously pass large volumes of condensate and are suitable for a wide range of process applications. Types include ball float and inverted bucket steam traps. This tutorial considers the operation and benefits of both types.

Ball float steam trap

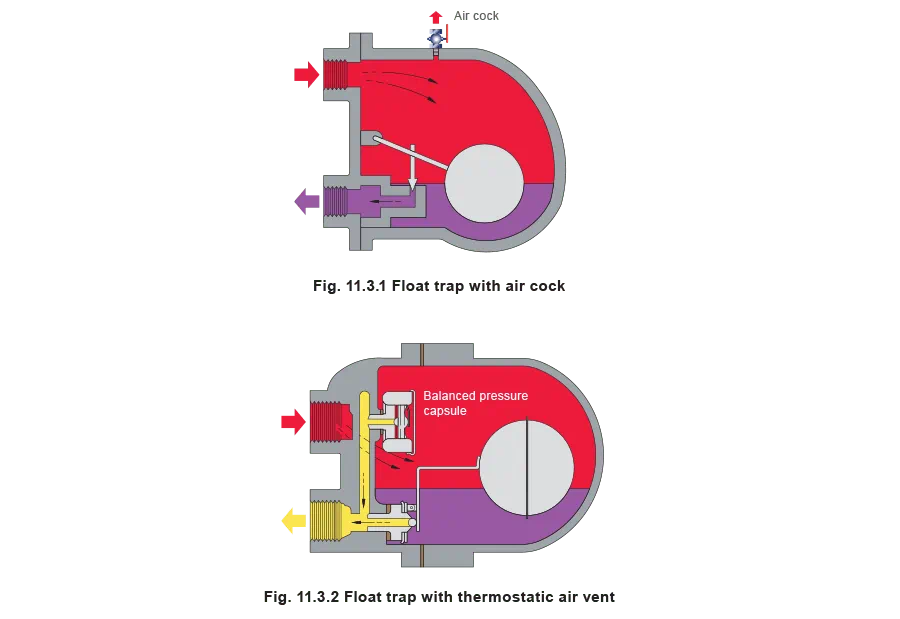

The ball float type trap operates by sensing the difference in density between steam and condensate. In the case of the trap shown in Figure 11.3.1, condensate reaching the trap will cause the ball float to rise, lifting the valve off its seat and releasing condensate. As can be seen, the valve is always flooded and neither steam nor air will pass through it, so early traps of this kind were vented using a manually operated cock at the top of the body. Modern traps use a thermostatic air vent, as shown in Figure 11.3.2. This allows the initial air to pass whilst the trap is also handling condensate.

The automatic air vent uses the same balanced pressure capsule element as a thermostatic steam trap, and is located in the steam space above the condensate level. After releasing the initial air, it remains closed until air or other non-condensable gases accumulate during normal running and cause it to open by reducing the temperature of the air/steam mixture. The thermostatic air vent offers the added benefit of significantly increasing condensate capacity on cold start-up.

In the past, the thermostatic air vent was a point of weakness if waterhammer was present in the system. Even the ball could be damaged if the waterhammer was severe. However, in modern float traps the air vent is a compact, very robust, all stainless steel capsule, and the modern welding techniques used on the ball makes the complete float-thermostatic steam trap very robust and reliable in waterhammer situations.

In many ways the float-thermostatic trap is the closest to an ideal steam trap. It will discharge condensate as soon as it is formed, regardless of changes in steam pressure.

Advantages of the float-thermostatic steam trap

- The trap continuously discharges condensate at steam temperature. This makes it the first choice for applications where the rate of heat transfer is high for the area of heating surface available.

- It is able to handle heavy or light condensate loads equally well and is not affected by wide and sudden fluctuations of pressure or flowrate.

- As long as an automatic air vent is fitted, the trap is able to discharge air freely.

- It has a large capacity for its size.

- The versions which have a steam lock release valve are the only type of trap entirely suitable for use where steam locking can occur.

- It is resistant to waterhammer.

Disadvantages of the float-thermostatic steam trap

- Although less susceptible than the inverted bucket trap, the float type trap can be damaged by severe freezing and the body should be well lagged, and/or complemented with a small supplementary thermostatic drain trap, if it is to be fitted in an exposed position.

- As with all mechanical type traps, different internals are required to allow operation over varying pressure ranges. Traps designed to operate on higher differential pressures have smaller orifices to balance the bouyancy of the float. If a trap is subjected to higher differential pressure than intended, it will close and not pass condensate.

Inverted bucket steam trap

The inverted bucket steam trap is shown in Figure 11.3.3. As its name implies, the mechanism consists of an inverted bucket which is attached by a lever to a valve. An essential part of the trap is the small air vent hole in the top of the bucket. Figure 11.3.3 shows the method of operation. In (i) the bucket hangs down, pulling the valve off its seat. Condensate flows under the bottom of the bucket filling the body and flowing away through the outlet. In (ii) the arrival of steam causes the bucket to become buoyant, it then rises and shuts the outlet. In (iii) the trap remains shut until the steam in the bucket has condensed or bubbled through the vent hole to the top of the trap body. It will then sink, pulling the main valve off its seat. Accumulated condensate is released and the cycle is repeated.

In (ii), air reaching the trap at start-up will also give the bucket buoyancy and close the valve. The bucket vent hole is essential to allow air to escape into the top of the trap for eventual discharge through the main valve seat. The hole, and the pressure differential, are small so the trap is relatively slow at venting air. At the same time it must pass (and therefore waste) a certain amount of steam for the trap to operate once the air has cleared. A parallel air vent fitted outside the trap will reduce start-up times.

Advantages of the inverted bucket steam trap

- The inverted bucket steam trap can be made to withstand high pressures.

- Like a float-thermostatic steam trap, it has a good tolerance to waterhammer conditions.

- Can be used on superheated steam lines with the addition of a check valve on the inlet.

- Failure mode is usually open, so it’s safer on those applications that require this feature, for example turbine drains.

Disadvantages of the inverted bucket steam trap

- The small size of the hole in the top of the bucket means that this type of trap can only discharge air very slowly. The hole cannot be enlarged, as steam would pass through too quickly during normal operation.

- There should always be enough water in the trap body to act as a seal around the lip of the bucket. If the trap loses this water seal, steam can be wasted through the outlet valve. This can often happen on applications where there is a sudden drop in steam pressure, causing some of the condensate in the trap body to 'flash' into steam. The bucket loses its buoyancy an sinks, allowing live steam to pass through the trap orifice. Only if sufficient condensate reaches the trap will the water seal form again, and prevent steam wastage.

- If an inverted bucket trap is used on an application where pressure fluctuation of the plant can be expected, a check valve should be fitted on the inlet line in front of the trap. Steam and water are free to flow in the direction indicated, while reverse flow is impossible as the check valve would be forced onto its seat.

- The higher temperature of superheated steam is likely to cause an inverted bucket trap to lose its water seal. A check valve in front of the trap should be regarded as essential under such conditions. Some inverted bucket traps are manufactured with an integral check valve as standard.

- The inverted bucket trap is likely to suffer damage from freezing if installed in an exposed position with sub-zero ambient conditions. As with other types of mechanical traps, suitable lagging can overcome this problem if conditions are not too severe. If ambient conditions well below zero are to be expected, then it may be prudent to consider a more robust type of trap to do the job. In the case of mains drainage, a thermodynamic trap would be the first choice.

- Like the float trap, the orifice in an inverted bucket trap designed to operate up to a maximum differential pressure. If the trap is subjected to a higher differential pressure than intended, it will close and not pass condensate. A range of orifice sizes is available to cover a wide range of pressure.

Highlighted products

BT6 Balanced Pressure Steam Trap

The BT6 316L stainless steel balanced pressure steam trap is specifically designed for hygienic applications including steam barriers, CIP/SIP and process vessel drainage, sterilisers and autoclaves, and culinary steam mains drainage.

FTS14 Ball Float Steam Trap

The requirement for 316 stainless steel is gradually being extended to secondary side media such as steam and hot water.

TD62M and TD62LM

The TD62LM and TD62M are maintainable high pressure thermodynamic steam traps with integral strainer and a replaceable seat to ease maintenance.