Introduction

Contents

Steam and the Organisation

The benefits described are not of interest to all steam users. The benefits of steam, as a problem solver, can be subdivided according to different viewpoints within a business. They are perceived differently depending on whether you are a chief executive, a manager or at operating level.

The questions these people ask about steam are markedly different.

Chief executive

The highest level executive is concerned with the best energy transfer solution to meet the strategic and financial objectives of the organisation.

If a company installs a steam system or chooses to upgrade an existing system, a significant capital investment is required, and the relationship with the system, and the system provider, will be long and involved.

Chief executives and senior management want answers to the following questions:

Q. What kind of capital investment does a steam system represent?

A steam system requires only small bore pipes to satisfy a high heat requirement. It does not require costly pumps or balancing, and only two-port valves are required.

This means the system is simpler and less expensive than, for example, a high temperature hot water system. The high efficiency of steam plant means it is compact and makes maximum use of space, something which is often at a premium within plant.

Furthermore, upgrading an existing steam system with the latest boilers and controls typically represents 50% of the cost of removing it and replacing it with a decentralised gas fired system.

Q. How will the operating and maintenance costs of a steam system affect overhead costs?

Centralised boiler plant is highly efficient and can use low interruptible tariff fuel rates. The boiler can even be fuelled by waste, or form part of a state-of-the-art Combined Heat and Power plant.

Steam equipment typically enjoys a long life - figures of thirty years or more of low maintenance life are quite usual.

Modern steam plant, from the boiler house to the steam using plant and back again, can be fully automated. This dramatically cuts the cost of manning the plant.

Sophisticated energy monitoring equipment will ensure that the plant remains energy efficient and has a low manning requirement.

All these factors in combination mean that a steam system enjoys a low lifetime cost.

Q. If a steam system is installed, how can the most use be made of it?

Steam has a range of uses. It can be used for space heating of large areas, for complex processes and for sterilisation purposes.

Using a hospital as an example, steam is ideal because it can be generated centrally at high pressure, distributed over long distances and then reduced in pressure at the point of use. This means that a single high pressure boiler can suit the needs of all applications around the hospital, for example, heating of wards, air humidification, cooking of food in large quantities and sterilisation of equipment.

It is not as easy to cater for all these needs with a water system.

Q. What if needs change in the future?

Steam systems are flexible and easy to add to. They can grow with the company and be altered to meet changing business objectives.

Q. What does using steam say about the company?

The use of steam is environmentally responsible. Companies continue to choose steam because it is generated with high levels of fuel efficiency. Environmental controls are increasingly stringent, even to the extent that organisations have to consider the costs and methods of disposing of plant before it is installed. All these issues are considered during the design and manufacture of steam plant.

Management level

A manager will consider steam as something that will provide a solution to a management problem, as something that will benefit and add value to the business. The manager’s responsibility is to implement initiatives ordered by senior executives. A manager would ask “How will steam enable successful implementation of this task?”

Managers tend to be practical and focused on completing a task within a budget. They will choose to use steam if they believe it will provide the greatest amount of practicality and expediency, at a reasonable cost.

They are less concerned with the mechanics of the steam system itself. A useful perspective would be that the manager is the person who wants the finished product, without necessarily wanting to know how the machinery that produces it is put together.

Managers need answers to the following questions:

Q. Will steam be right for the process?

Steam serves many applications and uses. It has a high heat content and gives up its heat at a constant temperature. It does not create a temperature gradient along the heat transfer surface, unlike water and thermal oils, which means that it may provide more consistent product quality. As steam is a pure fluid, it can be injected directly into the product or made to surround the product being heated. The energy given to the process is easy to control using two-port valves, due to the direct relationship between temperature and pressure.

Q. If a steam system is installed, how can the most use be made of it?

Steam Steam has a wide variety of uses. It can be used for space heating over large areas, and for many complex manufacturing processes.

On an operational level, condensate produced by a manufacturing process can be returned to the boiler feedtank. This can significantly reduce the boiler fuel and water treatment costs, because the water is already treated and at a high temperature.

Lower pressure steam can also be produced from the condensate in a flash vessel, and used in low pressure applications such as space heating

Q. What does steam cost to produce?

Water is plentiful and inexpensive, and steam boilers are highly efficient because they extract a large proportion of the energy contained within the fuel. As mentioned previously, central boiler plant can take advantage of low interruptible fuel tariffs, something which is not possible for decentralised gas systems which use a constant supply of premium rate fuel.

Flash steam and condensate can be recovered and returned to the boiler or used on low pressure applications with minimal losses.

Steam use is easy to monitor using steam flowmeters and SCADA compatible products.

For real figures, see ‘The cost of raising steam’, later in this Module.

In terms of capital and operating costs, it was seen when answering the concerns of the chief executive that steam plant can represent value for money in both areas.

Q. Is there enough installation space?

The high rates of heat transfer enjoyed by steam means that the plant is smaller and more compact than water or thermal oil plant. A typical modern steam to hot water heat exchanger package rated to 1 200 kW occupies only 0.7 m² floor space. Compare this to a hot water calorifier which may take up a large part of a plant room.

Q. Not wishing to think too much about this part of the process, can a total solution be provided?

Steam plant can be provided in the form of compact ready-to-install packages which are installed, commissioned and ready to operate within a very short period of time. They offer many years of trouble-free operation and have a low lifetime cost.

Technical personnel/operators

At the operating level, the day-to-day efficiency and working life of individuals can be directly affected by the steam plant and the way in which it operates. These individuals want to know that the plant is going to work, how well it will work, and the effect this will have on their time and resources.

Technical personal/operators need answers to the following questions:

Q. Will it break down?

A well designed and maintained steam plant should have no cause to break down. The mechanics of the system are simple to understand and designed to minimise maintenance. It is not unusual for items of steam plant to enjoy 30 or 40 years of trouble-free life.

Q. When maintenance is required, how easy is it?

Modern steam plant is designed to facilitate rapid easy maintenance with minimum downtime.

The modern design of components is a benefit in this respect. For example, swivel connector steam traps can be replaced by undoing two bolts and slotting a new trap unit into place. Modern forged steam and condensate manifolds incorporate piston valves which can be maintained inline with a simple handheld tool.

Sophisticated monitoring systems target the components that really need maintenance, rather than allowing preventative maintenance to be carried out unnecessarily on working items of plant.

Control valve internals can simply be lifted out and changed in-line, and actuators can be reversed in the field. Mechanical pumps can be serviced, simply by removing a cover, which has all the internals attached to it. Universal pipeline connectors allow steam traps to be replaced in minutes.

An important point to note is that when maintenance of the system is required, a steam system is easy to isolate and will drain rapidly, meaning that repairs can be quickly actioned. Any minor leaks that do occur are non-toxic. This is not always the case with liquid systems, which are slower and more costly to drain, and may include toxic or difficult to handle thermal fluids.

A steam system requires maintenance just like any other important part of the plant, but thanks to today’s modern steam plant design, manning and maintenance requirements and the lifetime costs of the system are low. For example, modern boiler houses are fully automated. Feedwater treatment and heating burner control, boiler water level, blowdown and alarm systems are all carried out by automatic systems. The boiler can be left unmanned and only requires testing in accordance with local regulations.

Similarly, the steam plant can be managed centrally using automatic controls, flowmetering and monitoring systems. These can be integrated with a SCADA system.

Manning requirements are thus minimised.

Industries and processes which use steam:

Table 1.2.1 Steam users

| Heavy users | Medium users | Light users |

|

Food and drinks Pharmaceuticals Oil refining Chemicals Plastics Pulp and paper Sugar refining Textiles Metal processing Rubber and tyres Shipbuilding Power generation |

Heating and ventilating Cooking Curing Chilling Fermenting Treating Cleaning Melting Baking Drying |

Electronics Horticulture Air conditioning Humidifying |

Interesting uses for steam:

- Shrink-wrapping meat.

- Depressing the caps on food jars.

- Exploding corn to make cornflakes.

- Dyeing tennis balls.

- Repairing underground pipes (steam is used to expand and seal a foam which has been pumped into the pipe. This forms a new lining for the pipe and seals any cracks).

- Keeping chocolate soft, so it can be pumped and moulded.

- Making drinks bottles look attractive but safe, for example tamper-proof, by heat shrinking a film wrapper.

- Drying glue (heating both glue and materials to dry on a roll).

- Making condoms.

- Making bubble wrap.

- Peeling potatoes by the tonne (high pressure steam is injected into a vessel full of potatoes. Then it is quickly depressurised, drawing the skins off).

- Heating swimming pools.

- Making instant coffee, milk or cocoa powder.

- Moulding tyres.

- Ironing clothes.

- Making carpets.

- Corrugating cardboard.

- Ensuring a high quality paint finish on cars.

- Washing milk bottles.

- Washing beer kegs.

- Drying paper.

- Ensuring medicines and medical equipment are sterile.

- Cooking potato chips.

- Sterilising wheelchairs.

- Cooking pieces of food, for example seafood, evenly in a basket using injected steam for heat, moisture and turbulence at the same time.

- Cooking large vats of food by direct injection or jacket heating.

……and hundreds more.

The cost of raising steam

In today’s industry, the cost of supplying energy is of enormous interest. Table 1.2.2 shows provisional industrial fuel prices for Great Britain, obtained from a recent Digest of UK Energy Statistics.

Table 1.2.2 GB fuel prices (excluding Climate Change Levy)

| Fuel | Size of consumer | 2009 |

| Coal (£ per tonne) | Small | 120.19 |

| Medium | 82.23 | |

| Large | 54.82 | |

| Heavy fuel oil (£ per tonne) | Small | 421.9 |

| Medium | 378.6 | |

| Large | 376.5 | |

| Gas oil (£ per tonne) | Small | 507.6 |

| Medium | 506 | |

| Large | 481.8 | |

| Electricity (pence per kWh) | Small | 9.82 |

| Medium | 8.84 | |

| Large | 6.48 | |

| Gas (pence per kWh) | Small | 2.93 |

| Medium | 2.53 | |

| Large | 1.8 |

The cost of raising steam based on the above costs

All figures exclude the Climate Change Levy which came into force in April 2001. The cost of raising 1 000 kg of steam using the fuel types listed and average fuel cost figures is shown in Table 1.2.3.

Table 1.2.3 GB steam costs - 2009

| Fuel | Average unit cost (£) | Unit of supply | Cost of raising 1 000 kg of steam (£) | |

| Oil | Heavy (3 500 s) | 0.366 0 | Per litre | 27.13 |

| Gas oil (35 s) | 0.400 0 | Per litre | 27.64 | |

| Natural gas | Firm | 0.020 0 | Per kWh | 16.98 |

| Interruptible | 0.018 0 | Per kWh | 15.28 | |

| Coal | 59.600 0 | Per Tonne | 6.07 | |

| Electricity | 0.072 7 | Per kWh | 49.37 | |

Boiler efficiency

A modern steam boiler will generally operate at an efficiency of between 80 and 85%. Some distribution losses will be incurred in the pipework between the boiler and the process plant equipment, but for a system insulated to current standards, this loss should not exceed 5% of the total heat content of the steam. Heat can be recovered from blowdown, flash steam can be used for low pressure applications, and condensate is returned to the boiler feedtank. If an economiser is fitted in the boiler flue, the overall efficiency of a centralised steam plant will be around 87%.

This is lower than the 100% efficiency realised with an electric heating system at the point of use, but the typical running costs for the two systems should be compared. It is clear that the cheapest option is the centralised boiler plant, which can use a lower, interruptible gas tariff rather than the full tariff gas or electricity, essential for a point of use heating system. The overall efficiency of electricity generation at a power station is approximately 30 to 35%, and this is reflected in the unit charges.

Components within the steam plant are also highly efficient. For example, steam traps only allow condensate to drain from the plant, retaining valuable steam for the process. Flash steam from the condensate can be utilised for lower pressure processes with the assistance of a flash vessel.

The following pages introduce some real life examples of situations in which a steam user had, initially, been poorly advised and/or had access to only poor quality or incomplete information relating to steam plant. In both cases, they almost made decisions which would have been costly and certainly not in the best interests of their organisation.

Some identification details have been altered.

Case study: UK West Country hospital considers replacing their steam system

In one real life situation in the mid 1990’s, a hospital in the West of England considered replacing their aged steam system with a high temperature hot water system, using additional gas fired boilers to handle some loads. Although new steam systems are extremely modern and efficient in their design, older, neglected systems are sometimes encountered and this user needed to take a decision either to update or replace the system.

The financial allocation to the project was £2.57 million over three years, covering professional fees plus VAT.

It was shown, in consultation with the hospital, that only £1.2 million spent over ten years would provide renewal of the steam boilers, pipework and a large number of calorifiers. It was also clear that renewal of the steam system would require a much reduced professional input. In fact, moving to high temperature hot water (HTHW) would cost over £1.2 million more than renewing the steam system.

The reasons the hospital initially gave for replacing the steam system were:

- With a HTHW system, it was thought that maintenance and operating costs would be lower.

- The existing steam plant, boilers and pipework needed replacing anyway.

Maintenance costs for the steam system were said to include insurance of calorifiers, steam trap maintenance, reducing valves and water treatment plant, also replacement of condensate pipework.

Operating costs were said to include water treatment, make-up water, manning of the boiler house, and heat losses from calorifiers, blowdown and traps.

The approximate annual operating costs the hospital was using for HTHW versus steam, are given in the Table 1.2.4.

Table 1.2.4 Operating costs

| Utility | Steam (£) | HTHW (£) |

| Fuel | 245 000 | 217 500 |

| Attendance | 57 000 | 0 |

| Maintenance | 77 000 | 40 000 |

| Water treatment | 8 000 | 0 |

| Water | 400 | 100 |

| Electricity | 9 000 | 12 000 |

| Spares | 10 000 | 5 000 |

| Total | £406 400 | £274 600 |

Additional claims in favour of individual gas fired boilers were given as:

- No primary mains losses.

- Smaller replacement boilers.

- No stand-by fuel requirement.

The costings set out above made the HTHW system look like the more favourable option in terms of operating costs.

The new HTHW system would cost £1 953 000 plus £274 600 per annum in operating and maintenance costs. This, in effect, meant decommissioning a plant and replacing it at a cost in excess of £2 million, to save just over £130 000 a year.

The following factors needed to be taken into account:

- The £130 000 saving using HTHW is derived from £406 400 - £274 600. The steam fuel cost can be reduced to the same level as for HTHW by using condensate return and flash steam recovery. This would reduce the total by £65 000 to £341 400.

- The largest savings claimed were due to the elimination of manned boilers. However, modern boiler houses are fully automated and there is no manning requirement.

- The £37 000 reduction in maintenance costs looked very optimistic considering that the HTHW solution included the introduction of 16 new gas fired boilers, 4 new steam generators and 9 new humidifiers. This would have brought a significant maintenance requirement.

- The steam generators and humidifiers had unaccounted for fuel requirements and water treatment costs. The fuel would have been supplied at a premium rate to satisfy the claim that stand-by fuel was not needed. In contrast, centralised steam boilers can utilise low cost alternatives at interruptible tariff.

- The savings from lower mains heat losses (eliminated from mains-free gas fired boilers) were minimal against the total costs involved, and actually offset by the need for fuel at premium tariff.

- A fact given in favour of replacing the steam system was the high cost of condensate pipe replacement. This statement tells us that corrosion was taking place, of which the commonest cause is dissolved gases, which can be removed physically or by chemical treatment. Removing the system because of this is like replacing a car because the ashtrays are full!

- A disadvantage given for steam systems was the need for insurance inspection of steam/ water calorifiers. However, HTHW calorifiers also require inspection!

- A further disadvantage given was the need to maintain steam pressure reducing valves. But water systems contain three-port valves with a significant maintenance requirement.

- The cost of make-up water and water treatment for steam systems was criticised. However, when a steam system requires maintenance, the relevant part can be easily isolated and quickly drained with few losses (this minimises downtime). In contrast, a water system requires whole sections to be cooled and then drained off. It must then be refilled and purged of air after maintenance. HTHW systems also require chemical treatment, just like steam systems.

Presented with these explanations, the hospital realised that much of the evidence they had been basing their decision on was biased and incomplete. The hospital engineering team reassessed the case, and decided to retain their steam plant and bring it up to date with modern controls and equipment, saving a considerable amount of money.

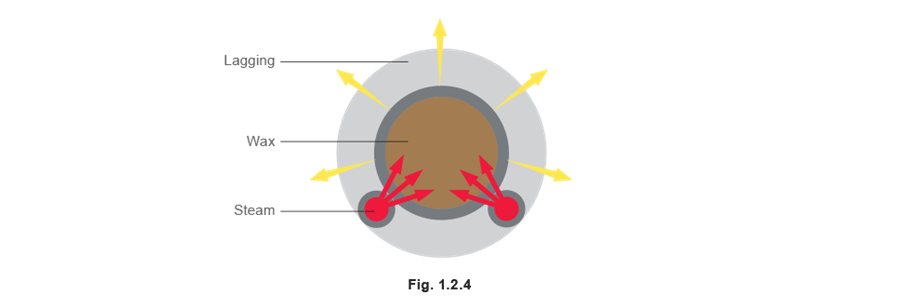

Trace heating

Trace heating is a vital element in the reliable operation of pipelines and storage/process vessels, across a broad range of industries.

A steam tracer is a small steam pipe which runs along the outer surface of a (usually) larger process pipe. Heat conductive paste is often used between the tracer and the process pipe. The two pipes are then insulated together. The heat provided from the tracer (by conduction) prevents the contents of the larger process pipe from freezing (anti-frost protection for water lines) or maintains the temperature of the process fluid so that it remains easy to pump.

Tracing is commonly found in the oil and petrochemical industries, but also in the food and pharmaceutical sectors, for oils, fats and glucose. Many of these fluids can only be pumped at temperatures well above ambient. In chemical processing, a range of products from acetic acid through to asphalt, sulphur and zinc compounds may only be moved through pipes if maintained at a suitable temperature.

For the extensive pipe runs found in much of process industry, steam tracing remains the most popular choice. For very short runs or where no steam supply is available, electrical tracing is often chosen, although hot water is also used for low temperature requirements. The relative benefits of steam and electric tracing are summarised in Table 1.2.5.

Table 1.2.5 The relative merits of steam and electric trace heating

| Steam trace heating | Electric trace heating | |

| Robustness - ability to resist adverse weather and physical abuse | Good | Poor |

| Flexibility - ability to meet demands of different products | Excellent | Poor |

| Safety - suitability for use in hazardous areas | Excellent | Cannot be used in all zones |

| Energy costs per GJ | 0 to £7.70 | £22.00 |

| System life | Long | Limited |

| Reliability | High | High |

| Ease by which the system can be extended | Easy | Difficult |

| Temperature control - accuracy of maintaining temperature | Very good/High | Excellent |

| Suitability for large plant | Excellent | Moderate |

| Suitability for small plant | Moderate | Good |

| Ease of tracer installation | Moderate | Requires specialist skills |

| Cost of maintenance | Low | Moderate |

| Specialised maintenance staff requirement | No | Yes |

| Availability as turnkey project | Yes | Yes |

Case study: UK oil refinery uses steam tracing for 4 km pipeline

In 1998, a steam trace heating system was installed at one of the UK’s largest oil refineries.

Background

The oil company in question is involved in the export of a type of wax product. The wax has many uses, such as insulation in electric cabling, as a resin in corrugated paper and as a coating used to protect fresh fruit.

The wax has similar properties to candle wax. To enable it to be transported any distance in the form of a liquid, it needs to be maintained at a certain temperature. The refinery therefore required a pipeline with critical tracing.

The project required the installation of a 200 mm diameter product pipeline, which would run from a tank farm to a marine terminal out at sea – a pipeline of some 4 km in length.

The project began in April 1997, installation was completed in August 1998, and the first successful export of wax took place a month later.

Although the refinery management team was originally committed to an electric trace solution, they were persuaded to look at comparative design proposals and costings for both electric and steam trace options.

The wax application

The key parameter for this critical tracing application was to provide tight temperature control of the product at 80°C, but to have the ability to raise the temperature to 90°C for start-up or re-flow conditions. Other critical factors included the fact that the product would solidify at temperatures below 60°C, and spoil if subjected to temperatures above 120°C.

Steam was available on site at 9 bar g and 180°C, which immediately presented problems of excessive surface temperatures if conventional schedule 80 carbon steel trace pipework were to be used. This had been proposed by the contractor as a traditional steam trace solution for the oil company.

The total tracer tube length required was 11.5 km, meaning that the installation of carbon steel pipework would be very labour intensive, expensive and impractical. With all the joints involved it was not an attractive option.

However, today’s steam tracing systems are highly advanced technologically. Spirax Sarco and their partner on the project, a specialist tracing firm, were able to propose two parallel runs of insulated copper tracer tube, which effectively put a layer of insulation between the product pipe and the steam tracer. This enabled the use of steam supply at 9 bar g, without the potential for hot spots which could exceed the critical 120°C product limitation.

The installation benefit was that as the annealed ductile steam tracer tubing used was available in continuous drum lengths, the proposed 50 m runs would have a limited number of joints, reducing the potential for future leaks from connectors.

This provided a reliable, low maintenance solution.

After comprehensive energy audit calculations, and the production of schematic installation drawings for costing purposes, together with some careful engineering, the proposal was to use the existing 9 bar g distribution system with 15 mm carbon steel pipework to feed the tracing system, together with strainers and temperature controls. Carbon steel condensate pipework was used together with lightweight tracing traps which minimised the need for substantial fabricated supports.

The typical tracer runs would be 50 m of twin isolated copper tracer tubing, installed at the 4 and 8 o’clock positions around the product pipe, held to the product pipeline with stainless steel strap banding at 300 mm intervals.

The material and installation costs for steam trace heating were about 30% less than the electric tracing option. In addition, ongoing running costs for the steam system would be a fraction of those for the electrical option.

Before the oil company management would commit themselves to a steam tracing system, they not only required an extended product warranty and a plant performance guarantee, but also insisted that a test rig should be built to prove the suitability of the self-acting controlled tracer for such an arduous application.

Spirax Sarco were able to assure them of the suitability of the design by referral to an existing installation elsewhere on their plant, where ten self-acting controllers were already installed and successfully working on the trace heating of pump transfer lines.

The oil company was then convinced of the benefits of steam tracing the wax product line and went on to install a steam tracing system.

Further in-depth surveys of the 4 km pipeline route were undertaken to enable full installation drawings to be produced. The company was also provided with on-site training for personnel on correct practices and installation procedures.

After installation the heat load design was confirmed and the product was maintained at the required 80°C.

The oil company executives were impressed with the success of the project and chose to install steam tracing for another 300 m long wax product line in preference to electric tracing, even though they were initially convinced that electric tracing was the only solution for critical applications.