Pipeline ancillaries

Contents

Check Valves

Check (non-return) valves are installed in pipelines to allow flow in one direction only; helping to protect equipment and processes. The operation, benefits, applications and selection of different designs, including lift, disc, swing and wafer check valves are explained in this tutorial.

Check valves, or non-return valves, are installed in pipeline systems to allow flow in one direction only. They are operated entirely by reaction to the line fluid and therefore do not require any external actuation. In this text, the expected, or desired direction of flow is termed ‘forward flow’, flow in the opposite direction is ‘reverse flow’.

There are a number of reasons for using check valves, which include:

- Protection of any item of equipment that can be affected by reverse flow, such as flowmeters, strainers and control valves.

- To check the pressure surges associated with hydraulic forces, for example, waterhammer.

These hydraulic forces can cause a wave of pressure to run up and down pipework until the energy is dissipated.

Although check valves can effectively shut off reverse flow, they should never be used in place of an isolation valve to contain live steam, in a section of pipe.

As with isolation valves, there are a number of different check valve designs, each suited to specific applications. The different types of check valve and their applications are discussed in this module, along with the correct sizing method.

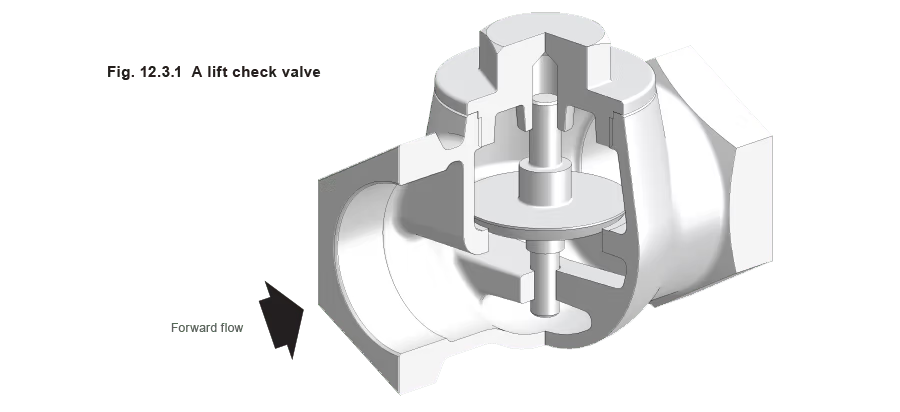

Lift check valves

Lift check valves are similar in configuration to globe valves, except that the disc or plug is automatically operated. The inlet and outlet ports are separated by a cone shaped plug that rests on a seat typically metal; in some valves, the plug may be held on its seat using a spring. When the flow into the valve is in the forward direction, the pressure of the fluid lifts the cone off its seat, opening the valve. With reverse flow, the cone returns to its seat and is held in place by the reverse flow pressure.

If a metal seat is used, the lift check valve is only suitable for applications where a small amount of leakage, under reverse flow conditions, is acceptable. Furthermore, the design of a lift check valve generally limits its use to water applications, subsequently, they are commonly used to prevent reverse flow of condensate in steam traps and on the outlets of cyclic condensate pumps.

The main advantage of the lift check valve lies in its simplicity, and as the cone is the only moving part, the valve is robust and requires little maintenance. In addition, the use of a metal seat limits the amount of seat wear. The lift check valve has two major limitations; firstly, it is designed only for installation in horizontal pipelines, and secondly, its size is typically limited to DN80, above which, the valve would become too bulky.

The piston-type lift check valve is a modification of the standard lift check valve. It incorporates a piston shaped plug instead of the cone, and a dashpot is applied to this mechanism. The dashpot produces a damping effect during operation, thereby eliminating the damage caused by the frequent operation of the valve, for example, in pipeline systems, which are subject to surges in pressure, or frequent changes in flow direction (one example would be a boiler outlet).

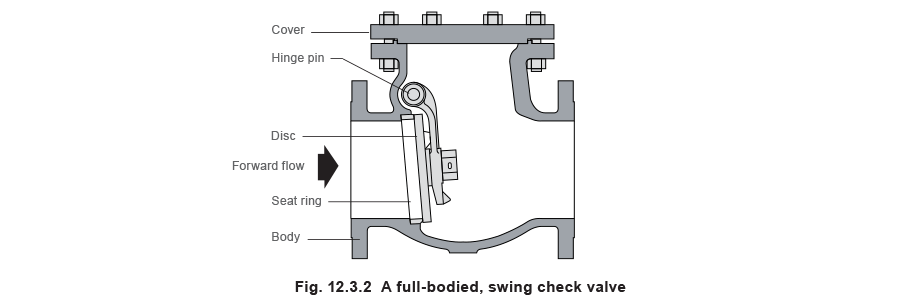

Swing check valves

A swing check valve consists of a flap or disc of the same diameter as the pipe bore, which hangs down in the flow path. With flow in the forwards direction, the pressure of the fluid forces the disc to hinge upwards, allowing flow through the valve. Reverse flow will cause the disc to shut against the seat and stop the fluid going back down the pipe. In the absence of flow, the weight of the flap is responsible for the closure of the valve; however, in some cases, closure may be assisted by the use of a weighted lever. As can be seen from Figure 12.3.2, the whole mechanism is enclosed within a body, which allows the flap to retract out of the flow path.

Swing check valves produce relatively high resistance to flow in the open position, due to the weight of the disc. In addition, they create turbulence, because the flap ‘floats’ on the fluid stream. This means that there is typically a larger pressure drop across a swing check valve than across other types.

With abrupt changes in flow, the disc can slam against the valve seat, which can cause significant wear of the seat, and generate waterhammer along the pipe system. This can be overcome by fitting a damping mechanism to the disc and by using metal seats to limit the amount of seat wear.

Wafer check valves

Both lift and swing check valves tend to be bulky which limits their size and makes them costly. To overcome this, wafer check valves have been developed. By definition wafer check valves are those that are designed to fit between a set of flanges. This broad definition covers a variety of different designs, including disc check valves and wafer versions of swing or split disc check valves.

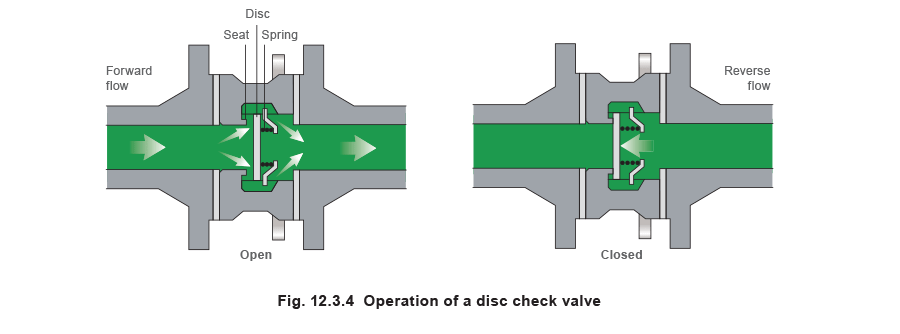

Disc check valves

The disc check valve consists of four main components: the body, a disc, a spring and a spring retainer. The disc moves in a plane at right angles to the flow of the fluid, resisted by the spring that is held in place by the retainer. The body is designed to act as an integral centring collar that facilitates installation. Where a ‘zero leakage’ seal is required, a soft seat can be included.

When the force exerted on the disc by the upstream pressure is greater than the force exerted by the spring, the weight of the disc and any downstream pressure, the disc is forced to lift off its seat, allowing flow through the valve. When the differential pressure across the valve is reduced, the spring forces the disc back onto its seat, closing the valve just before reverse flow occurs. This is shown in Figure 12.3.4. The presence of the spring enables the disc check valve to be installed in any direction.

The differential pressure required to open the check valve is mainly determined by the type of spring used. In addition to the standard spring, there are several spring options available:

- No spring - Used where the differential pressure across the valve is small.

- Nimonic spring - Used in high temperature applications.

- Heavy-duty spring - This increases the required opening pressure. When installed in the boiler feedwater line, it can be used to prevent steam boilers from flooding when they are unpressurised.

As with all wafer check valves, the size of the disc check valve is determined by the size of the associated pipework. This usually ensures that the valve is correctly sized, but there are cases where the valve is over or undersized.

An oversized check valve is often indicated by continuous valve chatter, which is the repeated opening and closing of the valve that occurs when the valve is only partially open. It is caused by the fact that when the valve opens, there is a drop in the upstream pressure; if this pressure drop means that the differential pressure across the valve falls below the required opening pressure, the valve will slam shut. As soon as the valve shuts, the pressure begins to build up again, and so the valve opens and the cycle is repeated.

Oversizing can usually be rectified by selecting a smaller valve, but it should be noted that this will increase the pressure drop across the valve for any one flow. If this is not acceptable, it may be possible to overcome the effects of chatter by reducing the closing force on the disc. This can be done either by using a standard spring instead of a heavy-duty one, or by removing the spring altogether. Another alternative is to use a soft seat; this does not prevent the chatter but rather, reduces the noise. Care must be taken however, as this may cause excessive wear on the seat.

Undersizing results in excessive pressure drop across the valve and, in the extreme, it may even prevent flow. The solution is to replace the undersized valve with a larger one.

Disc check valves are smaller and lighter than lift and standard swing check valves and subsequently cost less. The size of a disc check valve is however limited to DN125; above this, the design becomes complicated. Typically, such a design would include a cone shaped disc and a small diameter spring that is retained and guided along the centre line of the cone, which is more difficult and expensive to manufacture. Even then, such designs are still limited in size to DN250.

Standard disc check valves should not be used on applications where there is heavily pulsating flow, for example, on the outlet of a reciprocating air compressor, as the repeated impact of the disc can lead to failure of the spring retainer and high levels of stress in the spring. Specifically designed retainers are available for such applications. These designs typically reduce the amount of disc travel, which effectively increases the resistance to flow and therefore increases the pressure drop across the valve.

The design of disc check valves allows them to be installed in any position, including vertical pipelines where the fluid flows downwards.

Swing type wafer check valves

These are similar to the standard swing check valves, but do not have the full-bodied arrangement, instead, when the valve opens, the flap is forced into the top of the pipeline. Subsequently, the flap must have a smaller diameter than that of the pipeline, and because of this, the pressure drop across the valve, which is often high for swing type valves, is further increased.

Swing type check valves are used mainly on larger pipeline sizes, typically above DN125, because on smaller pipelines the pressure drop, caused by the disc ‘floating’ on the fluid stream, becomes significant. Furthermore, there are significant cost savings to be made by using these valves on larger sizes, due to the small amount of material required for the construction of the valve.

There is however one problem with using larger size valves; due to their size, the discs are particularly heavy, and therefore possess a large amount of kinetic energy when they close. This energy is transferred to the seat and process fluid when the valve slams shut, which could cause damage to the seat of the valve and generate waterhammer.

Wafer check valve applications

Wafer check valves are becoming the preferred type of check valve for most applications, due to their compact design and relatively low cost. The following is a list of some of their most common applications:

- Boiler feedlines - The check valve is used to prevent boiler water being forced back along the feedline into the storage tank when the feedpump stops running. Furthermore, a disc check valve with a heavy-duty spring and a soft seat can be fitted in the boiler feedline to prevent flow under gravity into the boiler when the feedpump is shut off.

- Steam traps - Other than with steam traps discharging to atmosphere, check valves should always be inserted after a steam trap to prevent back flow of condensate flooding the steam space. The check valve will also prevent the steam trap from becoming damaged by any hydraulic shock in the condensate line. It should be noted that when using blast discharge type steam traps, the check valve should be fitted at least 1 m downstream of the trap.

- Hot water circuits - A check valve should be installed after each pump to prevent reverse flow through the pump when it has been shut off (see Figure 12.3.8).

- Vacuum breakers - Check valves can be used as vacuum breakers, by fitting them in reverse. When a vacuum is created, the valve opens, allowing air to be drawn in from the atmosphere (see Figure 12.3.9).

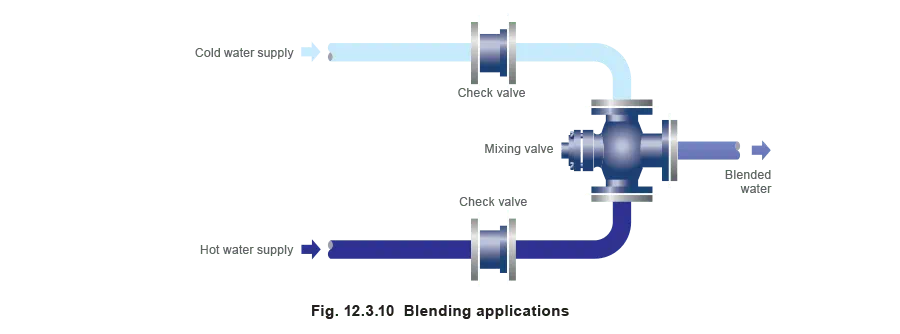

- Blending - A check valve should be fitted in each supply line to prevent reverse flow along the different lines which will lead to contamination. A common blending application is the mixing of hot and cold water to provide hot water (see Figure 12.3.10).

- Pipeline fitting protection - Check valves are used to prevent damage to equipment such as flowmeters and control valves, all of which can be damaged by reverse flow. Check valves also stop the contents of strainers from being deposited in upstream pipework by back flowing fluid.

- Multiple boiler applications - A check valve must be inserted on the outlet of each boiler to prevent any steam flowing into boilers, which may be on hot stand-by (see Figure 12.3.11).

- Blowdown vessels - When a blowdown vessel receives blowdown from more than one boiler, a wafer check valve should be installed on each separate blowdown line. This will prevent the blowdown from one boiler flowing back into another boiler. In many countries, this is a statutor requirement.

- Flash vessels - A wafer check valve is installed at the flash steam outlet from the flash vessel; this ensures that steam from any make-up valve does not flow back into the flash vessel (see Figure 12.3.12). A check valve is also installed after the steam trap that drains the flash vessel.

Split disc check valves

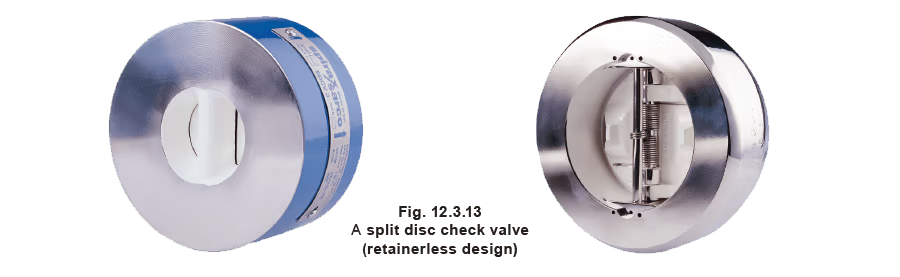

The split disc check valve or dual plate check valve is designed to overcome the size and pressure drop limitations of the swing and disc type wafer check valves. The flap of the swing check valve is essentially split and hinged down its centre, such that the two disc plates will only swing in one direction. The disc plates are held against the seat by a torsion spring mounted on the hinge.

In order to hold the hinge in the centre of the flow path, externally mounted retainer pins can be used. These retainer pins are a common source of leakage from the valve. An improved design secures the hinge internally, and as the valve mechanism is entirely sealed within the body, leakage to atmosphere is prevented (see Figure 12.3.13)

The valve is normally closed, as the disc plates are kept shut by the torsion spring. When fluid flows in the forwards direction, the pressure of the fluid causes the disc plates to hinge open, allowing flow. The check valve is closed by the spring as soon as flow ceases, before any reverse flow can occur.

The frequent opening and closing of the split disc check valve would soon cause seat damage if the heels of the disc plates were allowed to scuff against the seat during opening. To overcome this, the heel of the disc plates lift during the initial opening of the valve and the plates rotate purely on the hinge as opposed to the seat face.

The split disc type of check valve has several advantages over other types of check valves:

- The split disc design is not limited in size and these valves have been produced in sizes of up to DN5400.

- The pressure drop across the split disc check valve is significantly lower than across other types.

- They are capable of being used with lower opening pressures.

- Split disc check vales can be installed in any position, including vertical pipelines.

Other check valve types

The above mentioned types of check valve are the most commonly encountered types in steam, condensate, and liquid systems. However, several other types are also available. The three types listed below are mainly suited to liquid applications and subsequently may be found in condensate systems:

- Ball check valve - This consists of a rubber-coated ball that is normally seated on the inlet to the valve, sealing off the inlet. When pressure is exerted on the ball, it is moved off its seat along a guide rail, allowing fluid to pass through the inlet. When the fluid pressure drops, the ball slides back into its position on the inlet seat. Note: Ball check valves are typically only used in liquid systems, as it is difficult to obtain a tight seal using a ball.

- Diaphragm check valve - A flexible rubber diaphragm is placed in a mesh or perforated cone with the point in the direction of flow in the pipeline (see Figure 12.3.15). Flow in the forwards direction deflects the diaphragm inwards, allowing the free passage of the fluid. When there is no flow or a backpressure exists, the diaphragm returns to its original position, closing the valve. Note: The diaphragm material typically limits the application of the diaphragm check valve to fluids below 180°C and 16 bar.

- Tilting disc check valve - This is similar to the swing type check valve, but with the flap pivoted in front of its centre of pressure and counterweighted or spring loaded to assume a normally closed position (see Figure 12.3.16). When flow is in the forwards direction, the disc lifts and ‘floats’ in the stream offering minimum resistance to flow. The disc is balanced so that as flow decreases, it will pivot towards its closed position, closing before reverse flow actually commences. The operation is smooth and silent under most conditions. Note: due to thedesign of the tilting disc check valve, it is limited to use on liquid applications only.

Pressure loss charts

As most types of check valve are suitable for use on both liquid and gas systems, manufacturers typically show the pressure drop across a valve in the form of a pressure loss chart for water. A typical pressure loss chart is shown in Figure 12.3.17. It shows the pressure drop across a particular check valve for a given valve size and water flowrate in m³/ h.

In order to determine the pressure drop across the check valve for other liquids, the equivalent water volume flowrate needs to be calculated, this is done using the formula in Equation 12.3.1:

Once the equivalent water volume flowrate has been determined, the pressure drop across the valve can be read off the chart using the same method as for water, selecting the equivalent water volume flowrate instead of the actual volume flowrate.

It should be noted that the volumetric flowrate (in m³/h) is typically quoted for liquid applications, whereas, in steam applications, the mass flowrate (in kg/h) is normally used. To convert from kg/h to m³/h, the mass flowrate is multiplied by the specific volume (in kg/m³) for the particular working pressure and temperature (see Equation 12.3.2).

Alternatively, if te Kv value of the valve is specified, the pressure drop across the valve can be determined using the method outlined in Module 12.2.

Example 12.3.1

Determine the pressure drop across a DN65 check valve passing 1 200 kg/h of saturated steam at 8 bar g. Use the pressure drop characteristics shown in Figure 12.3.17.

Solution:

The first step is to calculate the volumetric flowrate:

From steam tables at 8 bar gauge, vg = 0.214 9 m³/kg

Using Figure 12.3.18, the pressure drop across the valve would be approximately 0.085 bar.